Table of Contents

- Understanding the Role of Spark Gaps in Stun Gun Performance

- Materials and Design Considerations for Optimal Spark Gap Efficiency

- Common Issues with Spark Gaps and How to Troubleshoot Them

- Best Practices for Maintaining and Enhancing Stun Gun Spark Gaps

- Future Outlook

Understanding the Role of Spark Gaps in Stun Gun Performance

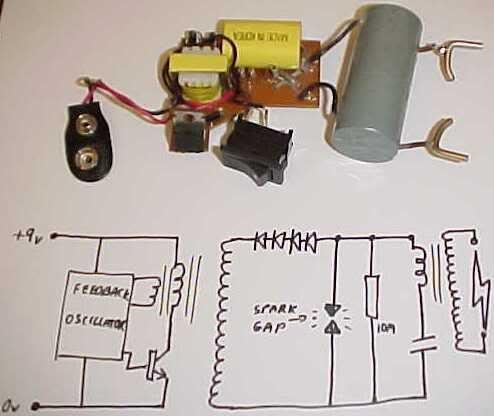

The spark gap is the silent powerhouse behind a stun gun’s ability to incapacitate effectively. It functions as a critical component that controls the electric arc between two electrodes. When activated, the spark gap allows a high-voltage current to jump across a controlled distance, producing the visible and functional spark that delivers the disabling shock. The size and consistency of this gap directly influence the intensity and reliability of the electrical discharge, making it an essential factor for optimal stun gun performance.

Several elements contribute to the spark gap’s efficiency, including electrode material, precise gap distance, and robust insulation. A finely tuned gap ensures that the stun gun discharges effectively regardless of environmental conditions like humidity or temperature. Moreover, the spark gap’s design impacts both the stun gun’s safety and longevity. Below are key considerations to understand:

- Optimal Gap Distance: Too wide a gap may cause unreliable arcs; too narrow may short-circuit the system.

- Durability of Electrodes: Materials such as tungsten or hardened steel extend the life of the spark gap under repeated use.

- Consistency of Discharge: Ensures the stun gun performs uniformly in high-stress situations.

Materials and Design Considerations for Optimal Spark Gap Efficiency

When approaching the design of spark gaps for stun guns, selecting the right materials is paramount to maximize efficiency and durability. Electrodes made from tungsten or copper alloys offer excellent conductivity and high melting points, reducing erosion during repeated discharges. The surface finish and shape of these electrodes also play a crucial role; smoother surfaces facilitate cleaner arcs while specialized shapes can concentrate the electrical field to improve ignition consistency. Additionally, insulating materials such as high-grade ceramics or advanced polymers must withstand heat and voltage stresses without breaking down, ensuring reliable performance over extended use.

Key considerations include:

- Thermal conductivity and resistance to electrode wear for sustained lifespan

- Electrical insulation capacity to prevent premature breakdown

- Precise electrode gap distance to optimize spark formation and minimize energy loss

- Material compatibility with device housing to prevent corrosion and mechanical failure

By meticulously balancing these factors in both material choice and geometric design, engineers can create spark gaps that deliver rapid, powerful discharges with minimal maintenance-an essential factor in the overall effectiveness and safety of stun gun operation.

Common Issues with Spark Gaps and How to Troubleshoot Them

Spark gaps, while critical for stun gun functionality, often encounter problems such as inconsistent sparks, reduced intensity, or complete failure to arc. These issues commonly stem from factors like electrode wear, dirty or corroded contacts, and environmental conditions (humidity, dust). Electrode misalignment can also cause uneven sparking or a weak stun effect, which directly impacts the device’s effectiveness. Regular inspection and cleaning of the spark gap area with a non-abrasive cloth can help maintain optimal performance and extend the lifespan of the electrodes.

When troubleshooting, consider these essential steps:

- Check electrode spacing: Ensure the gap distance matches manufacturer specifications, typically around 2-4 mm.

- Clean corrosion: Use a soft brush or cloth to remove any build-up on contacts that could impede electrical flow.

- Secure electrical connections: Loose wires or terminals can reduce current flow, impacting spark stability.

- Test under controlled conditions: Avoid testing in damp or dusty environments that may affect spark quality.

Best Practices for Maintaining and Enhancing Stun Gun Spark Gaps

Maintaining a stun gun’s spark gap in optimal condition is crucial for consistent performance and safety. One of the simplest yet most effective practices includes regular cleaning to prevent residue or oxidation build-up that can inhibit electrical flow. Use a soft brush or compressed air to gently remove debris without damaging the delicate components. Additionally, always store your device in a dry environment, as moisture can cause corrosion and reduce spark gap efficiency over time. Avoid using harsh chemicals or abrasive materials, which can erode the electrodes and shorten the lifespan of the spark gap.

Enhancing the functionality of spark gaps involves a few targeted maintenance routines that ensure maximum spark intensity and reliability. Here are some practical tips to keep in mind:

- Periodically inspect: Check for signs of wear or irregular sparking patterns, which may indicate electrode misalignment or erosion.

- Calibration adjustments: If your stun gun allows for it, fine-tuning the gap distance can optimize voltage output and stun effect.

- Replace worn components: Proactively swapping out electrodes or insulators when performance dips can prevent complete device failure.

- Use manufacturer-approved parts: Ensures compatibility and maintains device integrity during maintenance.

Future Outlook

In conclusion, spark gaps play a pivotal role in the functionality and effectiveness of stun guns. By understanding how these tiny yet powerful components facilitate rapid electrical discharges, we gain valuable insight into the science behind personal defense technology. Whether you’re a tech enthusiast or simply curious about how stun guns deliver their non-lethal force, appreciating the intricacies of spark gaps underscores the innovation fueling safer self-protection tools. As advancements continue, staying informed about these foundational elements helps us better grasp the evolving landscape of electrical safety devices.Check Our Other Blogs

- StunGun – Your Trusted Source for Stun Guns, Laws, and Self-Defense Tips

- PepperSprayLaws – Your Trusted Resource for Pepper Spray Information

- StunGunLaws – Your Trusted Guide to Stun Gun Legality and Safety