Table of Contents

- Understanding the Role of Spark Gaps in Stun Gun Functionality

- Technical Breakdown of Spark Gap Operation and Electrical Discharge

- Materials and Design Considerations for Optimal Spark Gap Performance

- Best Practices for Maintaining Spark Gaps to Ensure Stun Gun Reliability

- In Retrospect

Understanding the Role of Spark Gaps in Stun Gun Functionality

At the heart of a stun gun’s ability to incapacitate lies a tiny but powerful component known as the spark gap. This simple electrical gap between two conductive electrodes is engineered to break down under high voltage, creating a visible and audible spark. This spark effectively acts as a switch, allowing the stun gun to discharge a sudden burst of electrical energy. The spark gap’s precise spacing and material composition are crucial: too wide, and the voltage won’t jump the gap; too narrow, and the device risks short-circuiting prematurely. This balance ensures that the device delivers a controlled and high-voltage electric shock essential for its disabling effect.

Beyond just creating the spark, the gap also helps regulate the current flow that passes through the target, maintaining safety while maximizing effectiveness. Key factors contributing to the spark gap’s role include:

- Voltage threshold control: Ensures the stun gun activates only when the required voltage is reached.

- Energy discharge management: Facilitates the release of the electric charge in precise pulses, avoiding continuous flow that could cause unintended harm.

- Durability under repeated use: Crafted to withstand multiple discharges without deterioration, preserving the device’s longevity.

Technical Breakdown of Spark Gap Operation and Electrical Discharge

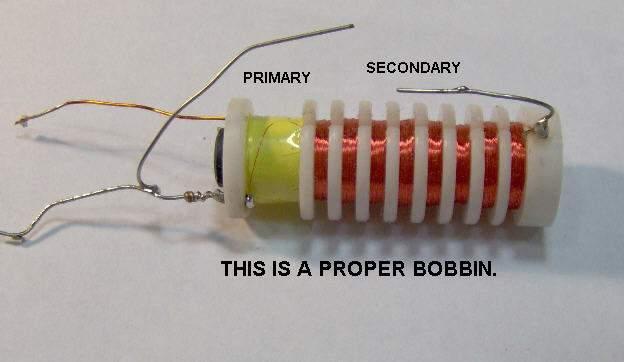

The core of a stun gun’s functionality lies in its ability to generate a controlled but intense electrical discharge through a spark gap. At the heart of this process is the creation of a rapid voltage spike across the electrodes separated by a small air gap. When the voltage difference reaches a critical threshold, it ionizes the air, turning it from an insulator into a conductor. This transition facilitates a sudden flow of electrons – a discharge current – that produces the characteristic spark. The spark gap acts as a switch that opens and closes in microseconds, enabling the stun gun to deliver high-voltage pulses without continuous energy drain.

Several key factors influence the spark gap’s operation and the resulting electrical discharge:

- Gap distance: A precisely calibrated distance controls the breakdown voltage; too wide, and the spark fails to form; too narrow, and the device risks continuous conduction.

- Electrode material and shape: These determine the arc stability and longevity by affecting electron emission efficiency and heat dissipation.

- Capacitor charge and discharge cycle: Charged capacitors supply the sudden energy burst necessary to ionize air and sustain the spark momentarily, ensuring a powerful electrical pulse hits the target.

Materials and Design Considerations for Optimal Spark Gap Performance

Selecting the right materials for the electrodes is critical to sustaining reliable spark generation while minimizing wear. Typically, electrodes crafted from or excel due to their high melting points, excellent conductivity, and resistance to erosion. Incorporating coatings such as silver or chromium can further enhance durability and reduce oxidation, ensuring consistent spark formation even after repeated activations. Additionally, the physical geometry of the electrodes – including the shape and surface finish – directly influences the spark’s intensity and stability. For instance, pointed or beveled edges tend to focus the electrical discharge more efficiently, reducing power loss and improving overall stun gun performance.

Beyond materials, thoughtful design choices optimize the spark gap’s operational efficiency and longevity. Maintaining a precise and adjustable gap distance allows the device to adapt to environmental variations like humidity or temperature that affect air conductivity. Integrating robust insulation and employing heat-resistant housing materials help manage thermal loads generated during rapid firing sequences. Other design considerations include vibration dampening features to maintain electrode alignment and prevent misfires, as well as compact layouts that balance device portability with electrical safety. Together, these elements form the backbone of a spark gap capable of reliably powering stun guns with maximum effectiveness.

- High melting point electrodes: Tungsten, copper alloys

- Protective coatings: Silver, chromium for oxidation resistance

- Electrode geometry: Pointed or beveled edges for focused discharges

- Adjustable gap spacing: Adapts to environmental factors

- Durable housing: Heat-resistant and vibration dampening

Best Practices for Maintaining Spark Gaps to Ensure Stun Gun Reliability

Maintaining the spark gap in your stun gun is vital to ensuring consistent performance and longevity. Regular inspection is key-look for signs of erosion or buildup on the metal contacts, which can interfere with the electrical discharge. Using a soft brush or compressed air to gently remove any debris can dramatically improve spark quality. It’s also important to avoid touching the contacts with your bare hands, as oils and dirt from your skin can reduce conductivity and cause premature wear.

Proactive care routines go beyond cleaning. Keeping the stun gun’s internal components dry and stored in a cool, dust-free environment prevents corrosion and moisture damage. Periodically test the device to confirm the spark gap is firing correctly, and if adjustment is possible, ensure the gap distance remains within manufacturer specifications. By following these simple yet effective practices, you maximize the reliability of your stun gun’s spark gap and, ultimately, its effectiveness in critical moments.

- Inspect gap contacts weekly for wear or deposits

- Clean gently with a dry brush or compressed air

- Store stun gun in a cool, dry place away from dust

- Wear gloves or use tools to avoid contamination

- Test the device regularly to ensure proper spark arc

In Retrospect

In summary, the humble spark gap plays a crucial role in the impressive performance of stun guns. By rapidly generating controlled electrical arcs, spark gaps enable these devices to deliver high-voltage pulses that effectively disrupt muscle control without causing permanent harm. Understanding this component not only sheds light on the engineering behind stun guns but also highlights the careful balance of safety and power that makes them reliable self-defense tools. Whether you’re a tech enthusiast or simply curious about how stun guns work, appreciating the spark gap’s function offers valuable insight into the fascinating world of non-lethal electrical devices.Check Our Other Blogs

- StunGun – Your Trusted Source for Stun Guns, Laws, and Self-Defense Tips

- PepperSprayLaws – Your Trusted Resource for Pepper Spray Information

- StunGunLaws – Your Trusted Guide to Stun Gun Legality and Safety